Industry 4.0 Solutions

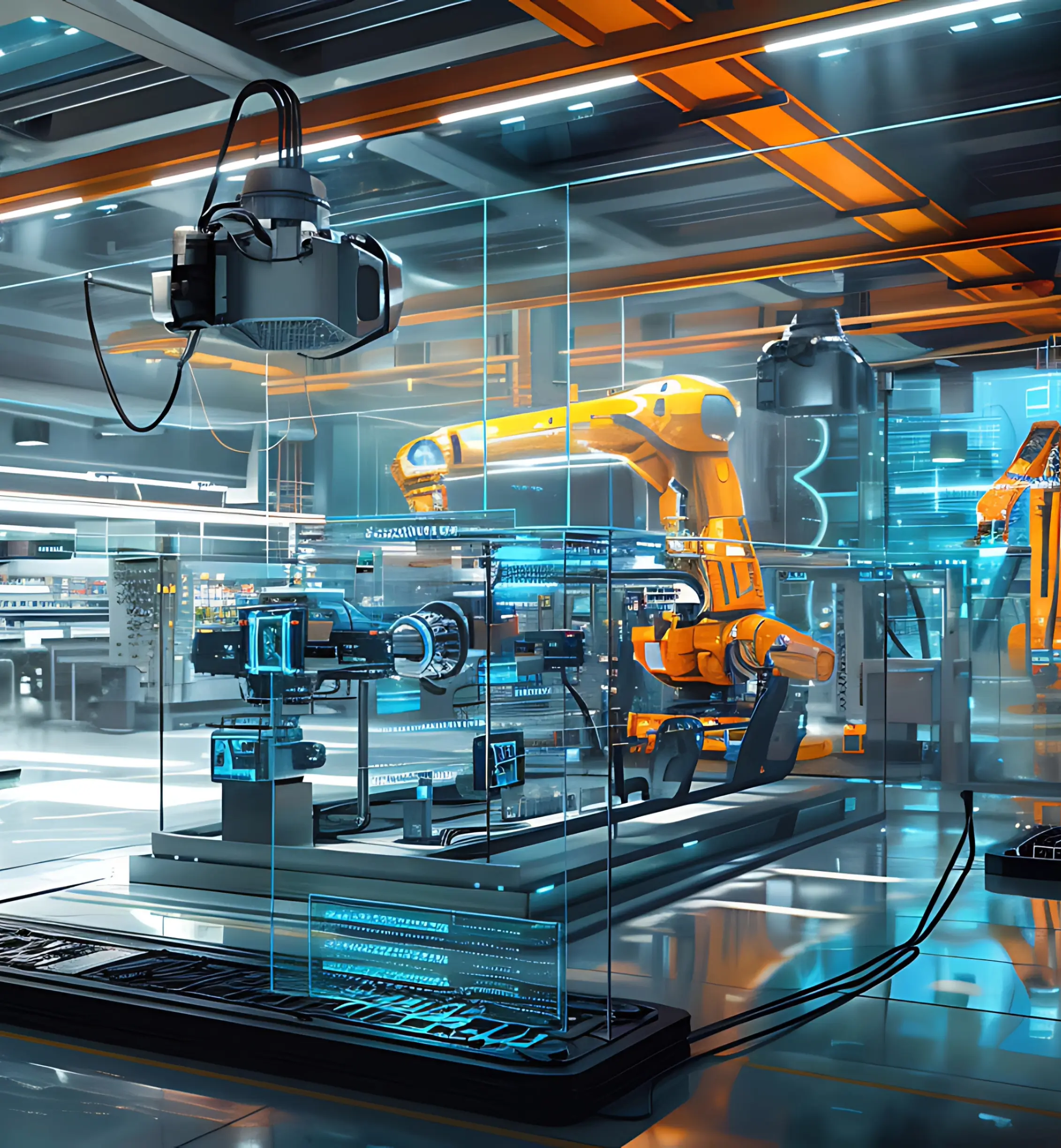

Transform Life Sciences manufacturing with Industry 4.0: Skellig Automation specializes in custom, scalable Industry 4.0 solutions for pharmaceutical and biotechnology manufacturing.

Skellig Automation’s Industry 4.0 Program

Our Industry 4.0 solutions will revolutionize Life Sciences manufacturing

Skellig Automation’s Industry 4.0 program aims to accelerate digital transformation in the Life Sciences. Our digital transformation projects begin with open architecture that centers accessible data through a Unified Namespace and data flow. Through long-term 4.0 engineering strategy and customized software solutions for each client, our projects speed time-to-market while reducing pharmaceutical manufacturing costs.

It all comes back to people: faster and more affordable manufacturing leads to better global health outcomes.

Let Skellig Automation guide your digital transformation journey

Our engineers are experts in developing modern automation strategies at all stages of digital transformation. Some of the most common services that we provide for clients of all sizes include:

- Digital transformation site assessments and project planning

- Manufacturing Execution System development, implementation, planning, and support

- Unified Namespace implementation

- MQTT and other data broker implementation

- Lab digitization services

- Automation architecture restructuring

- Ignition implementation

Industry 4.0 education can change the Life Sciences manufacturing landscape

Modern Life Sciences manufacturing requires education. Skellig Automation provides free Industry 4.0 education through our YouTube channel, white papers, blog posts, and industry events.

We have also developed a freely-accessible digital twin that demonstrates Industry 4.0 technology in action, including MQTT, Sparkplug B, a Unified Namespace (UNS), and Industrial DataOps. Read more about our digital twin below.

If you’re just starting your 4.0 education, learn the basic terminology with our ‘What Is’ series, where we break down the basics.

For those who have the basics covered, check out our regular livestream show, Lifestream, hosted by our 4.0 Solutions Architect Amy Williams. She breaks down tough Life Sciences manufacturing problems with modern technologies, showcases different software solutions, and invites guests from the industry.

VIRTUAL PLANT

Skellig’s Digital Twin Showcases Modern Automation Solutions

Our digital twin demonstrates new and experimental Industry 4.0 software solutions. The virtual plant’s first deployment centered Inductive Automation’s Ignition for process visualization, the Canary Labs Historian for data historization, and HiveMQ’s MQTT Broker for an MQTT infrastructure that creates a Unified Namespace.

MQTT Connects

At the core of Skellig’s virtual plant is a HiveMQ message broker. Data from various devices, edge nodes, and IT/OT systems traverses a pub/sub architecture.

The Unified Namespace Collects

Data published to the HiveMQ message broker is contextualized and readily available. See how a Unified Namespace (UNS) provides a single source of truth for data within Skellig’s virtual plant.

Sparkplug B Provides Consistency

Sparkplug B is an open-source specification that defines how the MQTT protocol sends and receives data. See the protocol in action as it transfers large amounts of industrial data

Industrial DataOps Provides Context

Both Inductive Automation’s Ignition and HighByte’s Intelligence Hub can easily connect, model, and deliver data. See how it is being used to contextualize data from plant-floor devices.

Request free access to Skellig’s Virtual Plant

Interested in learning more about our Industry 4.0 program? Contact us to learn more and see how we can help your facility. Fill out the form below or email us at info@skellig.com and we will be in touch!