The Humbling Reality of Biology

Early in my career, I learned a fundamental truth that continues to shape how I think about biomanufacturing today: biology is unbelievably complex, and we know surprisingly little about it.

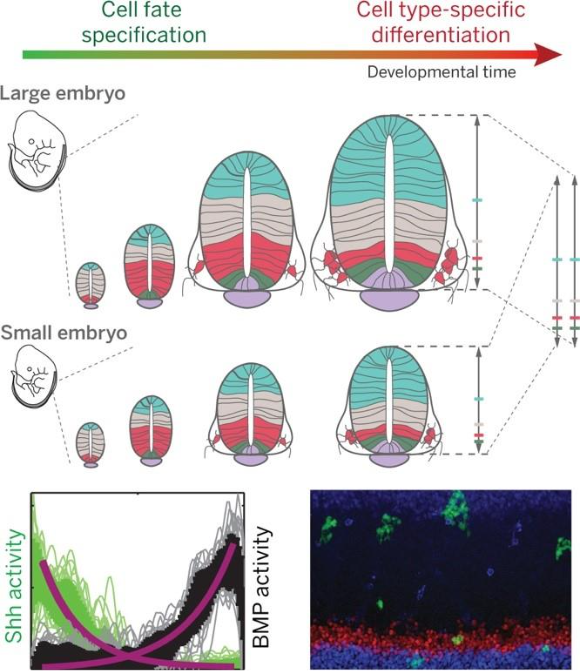

I spent eight years in the field of tissue engineering, trying to reverse engineer early spinal cord development. Evolution perfected this fundamental process of development eons ago, whereby cells are instructed spatially and temporally to create the multitude of neurons that comprise our spinal cords in precisely the correct location. Yet despite decades of research, we’ve barely scratched the surface of understanding how this process works.

The Challenges of Biomanufacturing

The same challenges found with trying to understand developmental biology applies to biomanufacturing, where we need to harness the cells innate ability to make ‘things’ in this case the things being proteins and more specifically monoclonal antibodies. As process engineers and process scientists our job is to make this manufacturing process repeatable- every batch needs to produce the same high-quality product. But, these are mammalian cells which are, at best, moderately understood and at worst are even inherently stochastic [cite]. We can grow these cells in controlled bioreactors and have a real time view of the pH and dissolved oxygen concentrations, but how do we know how many cells are in the bioreactor at any given time? Or how much food is available for them, or how much waste they are producing?

Biomanufacturing’s Data Problem

To answer these fundamental questions, we typically take samples and run them on at-line equipment like a ViCell or FLEX2. While these at-line tools are invaluable, this sampling approach creates two significant problems:

Problem #1: Extremely Low Data Fidelity

This method of sampling bioreactors is time-consuming, so its typically limited to once daily. This means that over the course of a typical mammalian cell culture process we get at most 14 to 20 data points for the entire run. 14 to 20 data points to understand a complex biological process that we already know very little about. This sparse data makes it virtually impossible to leverage machine learning or advanced analytics effectively.

Problem #2: Contamination Risk

Every time we take a sample, we introduce a risk of contamination that could cost us the entire batch. In an industry where a single batch can be worth millions of dollars, this risk adds up quickly.

What is Process Analytical Technology?

What if there was a better way? What if we could measure cell count, nutrient levels, and waste production using in-line probes—no different from the pH or dissolved oxygen sensors we already rely on?

This is exactly what Process Analytical Technology delivers: in-line, at-line, or online sensors that can measure the most critical process parameters in biomanufacturing.

From a data perspective the transformation is significant. Instead of 14 to 20 data points per run, PAT technologies can deliver 20 data points every 10 minutes. That’s over 14,000 data points in a single run! This is the type of rich dataset that can truly unlock the power of machine learning and artificial intelligence in biomanufacturing.

So what exactly is a process analytical technology? Many of these systems are optical including Raman, NIR, UV-VIS and refractive index. Others such as capacitance rely on the cells ability to become polarized like a battery. Lastly, some traditional technologies such as HPLC have been adapted to be at-line – providing critical quality measurements without the need for sending samples to the quality control labs.

Endorsed by the FDA

To me the most surprising part about any discussion around PAT is the fact that the FDA has been encouraging the industry to adopt these technologies for over two decades.

In October 2004, the FDA released a guidance document titled “PAT — A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance.” (https://www.fda.gov/regulatory-information/search-fda-guidance-documents/pat-framework-innovative-pharmaceutical-development-manufacturing-and-quality-assurance) In this document, they explicitly encouraged the industry to seriously consider these technologies to improve consistent product quality and achieve right-first-time manufacturing.

That was 20 years ago. The regulatory pathway has been clear, the technology has matured, and the business case continues to strengthen (see https://www.biophorum.com/news/how-to-maximize-business-value-from-process-analytical-technologieshow-to-maximize-business-value-from-process-analytical-technologies/). So why aren’t these technologies more widely adopted?

The Path Forward for Process Analytical Technology

The biomanufacturing industry stands at a crossroads. We can continue operating with limited process visibility, making critical decisions based on a handful of data points, or we can embrace the rich, real-time insights that PAT technologies provide.

The choice seems clear: it’s time to unlock the black box of bioprocessing and step into the data-rich future of biomanufacturing. The FDA is ready, the technology is proven, and the competitive advantages are substantial.

The question isn’t whether PAT will transform biomanufacturing, it’s whether your organization will be leading or following that transformation. If you’re ready to lead the charge, contact us today at info@skellig.com to get started on your facility’s PAT journey.